Products

01.

UV Systems

Ultra Violet technology goes a long way to alleviate the problem of grease build-up in duct systems

02.

Appliance Design

See appliances that we have designed and engineered.

01. UV Systems

Ultra Violet technology goes a long way to alleviate the problem of grease build-up in duct systems.

ULTRAVIOLET EXTRACTOR SYSTEMS

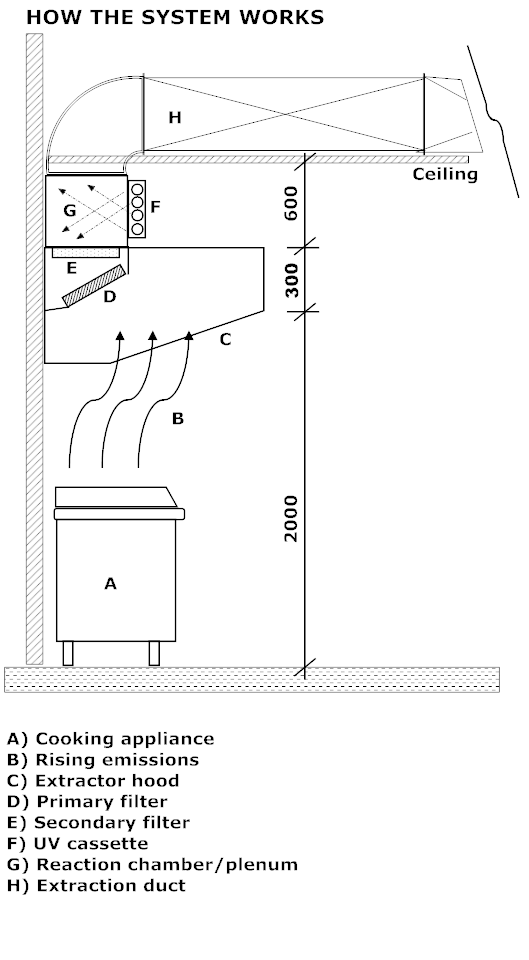

There is a growing recognition of the risks to health, fire hazard and air quality from cooking emissions. Some of the emitted mass is captured in the exhaust system and the balance is expelled into the atmosphere. The captured mass in the exhaust duct is the concern of the operator or building owner and the expelled pollutant is of concern for the enviroment.

Ultraviolet technology goes a long way to aleviate these problems, it is an effective method of eliminating grease build-up in duct systems as well as reducing cooking odours, killing germs and disinfecting air and surfaces which are exposed to it’s radiation.

ADVANTAGES OF UV TECHNOLOGY

Grease build up in extractor ducts is the number one fire hazard in any catering establishment. The duct system if not perfectly sealed, will allow unsightly black discharge to leak, drip on ceilings, run down the sides of vertical flues and expel onto roof-tops as well as fouling and jamming extractor fans. Once ignited, the grease acts as an accelerant and is very difficult to extinguish. This extreme hazard has huge financial implications. Regular de-greasing of extractor systems, as is required by law can be a very costly exercise.

Standard extractor canopy filters will remove between 80 and 85% of grease particles. Secondary filters which are incorporated in the UV System will again remove 80% of the remaining particles. UV radiation will now sterilize the airflow, remove odours and convert the remainder of fat particles before they pass through to the duct, into a fine NON-FLAMABLE powdery ash. Together with other naturally ocurring by-products, Oxygen, Ozone and Carbon Dioxide, this ash is then dispelled into the atmosphere.

CONSTRUCTION

The system is constructed in modules fabricated from 0,9mm TYPE 430 Stainless Steel with a # 4 Satin Scratch Finish. Joints are Lock-Formed and welded with no Pop Rivits or Bolts used. Standard Modules are 1600 x 1200mm. Customised Module sizes can be fabricated on request. Each 1600mm Module is fitted with a vapour proof recessed light fitting. Centrifical flow primary stainless steel filters extend from end to end across the length of the module to create a balanced airflow within the reaction chamber. These filters act as a retardant to prevent open flame from entering the hood. Secondary filters are incorporated to attain the correct size of particle in so ensuring the the complete oxydation by UV photolysis. These filters are fitted with safety micro-switches to prevent accidental exposure to the UV lamps. UV-C Germicidal lamps are mounted in a removable cassette for ease of service and replacement. The average replacement period for lamps is two years.

02. Appliance Design

See appliances that we have designed and engineered.

FOGONOVO Products

FOGONOVO PATIO GRILLER

FNDG3-AGT 3 BURNER TABLE MODEL GRILL 500 X 570 X 320 (54,000 BTU)

FNDG4-AGT 4 BURNER TABLE MODEL GRILL 600 X 570 X 320 (72,000 BTU)

FNDG6-AGT 6 BURNER TABLE MODEL GRILL 860 X 570 X 320 (108,000 BTU)

FOGONOVO MODULAR RANGE

FOGONOVO GAS CHAR GRILL MODULAR SERIES

CG4-FNM 4 BURNER GAS GRILL 575 X 710 X 300 (72,000 BTU)

CG6-FNM 6 BURNER GAS GRILL 820 X 710 X 300 (108,000 BTU)

CG8-FNM 8 BURNER GAS GRILL 1090 X 710 X 300 (144,000 BTU)

CG10-FNM 10 BURNER GAS GRILL 1266 X 710 X 300 (180,000 BTU)

CG12-FNM 12 BURNER GAS GRILL 1485 X 710 X 300 (216,000 BTU)

FOGONOVO GAS BOILING TABLE MODULAR SERIES

BT2-FNM 2 BURN STAG BOILING TBL 530 X 710 X 300 (36,000 BTU)

BT4-FNM 4 BURN STAG BOILING TBL 940 X 710 X 300 (72,000 BTU)

BT6-FNM 6 BURN STAG BOILING TBL1360 X 710 X 300 (108,000 BTU)

FOGONOVO ELECTRIC GRILL MODULAR SERIES

EG5-FN 575 ELECTRIC GRILL 575 X 710 X 300 6 Kw 24 amp

EG8-FN 820 ELECTRIC GRILL 820 X 710 X 300 8 Kw 32 amp

EG11-FN 1090 ELECTRICGRILL 1090 X 710 X 300 9 Kw 36 amp

EG15-FN 1485 ELECTRIC GRILL 1485 X 710 X 300 12 Kw 48 amp

FOGONOVO ELECTRIC FRYERS MODULAR SERIES

SF210 2 X 10 ltr/ PAN HIGH SPEED FRYER (575 X 710) 12 Kw 48 amp

SF120 I X 20 ltr/ PAN HIGH SPEED FRYER (480 X 710) 9 Kw 36 amp

SF220 2 X 20 ltr/ PAN HIGH SPEED FRYER (979 X 710) 18 Kw 72 amp

SF130 1 x 25 ltr /PAN HIGH SPEED FRYER (530 X 710) 12 Kw 48 amp

SF230 2 x 25 ltr/PAN HIGH SPEED FRYER (1075 X 710) 24 Kw 96 amp

AEROGAS Products

AEROGAS 600 series

AEROGAS GAS CHAR GRILL 600 SERIES

CG6-ATW 6 BURNER GAS GRILL 820 X 800 X 900, (126,000 BTU)

CG8-ATW 8 BURNER GAS GRILL 1090 X 800 X 900, (168,000 BTU)

CG10-ATW 10 BURNER GAS GRILL 1266 X 800 X 900, (210,000 BTU)

CG12-ATW 12 BURNER GAS GRILL 1485 X 800 X 900, (252,000 BTU)

AEROGAS ELECTRIC GRIDDLE 600 SERIES

EG8- ATEW 820 ELECTRIC GRILL 820 X 800 X 900 6 Kw

EG10-ATEW 1090 ELECTRIC GRILL 1090 X 800 X 900 9 Kw

EG12-ATEW 1266 ELECTRIC GRILL 1266 X 800 X 900 12 Kw

AEROGAS 400 series

AEROGAS GAS CHAR GRILL 400 SERIES

CG4 4 BURNER GAS GRILL 575 X 700 X 900 (72,000 BTU)

CG6 6 BURNER GAS GRILL 820 X 700 X 900 (108,000 BTU)

CG8 8 BURNER GAS GRILL 1090 X 700 X 900 (144,000 BTU)

CG10 10 BURNER GAS GRILL 1266 X 700 X 900 (180,000 BTU)

CG12 12 BURNER GAS GRILL 1485 X 700 X 900 (216,000 BTU)

AEROGAS Boiling Tables

AEROGAS GAS STOCK POT STOVES

BT1 1 BNR STOCKPOT STOVE 510 X 510 X 600 (18,000 BTU)

BT2 2 BNR STOCKPOT STOVE 910 X 510 X 600 (36,000 BTU)

BT3 3 BNR STOCKPOT STOVE 1315 X 510 X 600 (54,000 BTU)

BT4 4 BNR STOCKPOT STOVE 1720 X 510 X 600 (72,000 BTU)

AEROGAS GAS STAGGERED BOILING TABLE

BTS2 2 BNR STAG BOILING TBL 530 X 660 X 900 (36,000 BTU)

BTS4 4 BNR STAG BOILING TBL 940 X 660 X 900 (72,000 BTU)

BTS6 6 BNR STAG BOILING TBL1360 X 660 X 900 (108,000 BTU)

AEROTEC Products

AEROTEC Extractor Systems

EXTRACTOR SYSTEMS

We design and specify kitchen extractor systems for fabrication compliant to SANS 1850 regulations. All canopies are constructed with lock-formed or welded seams and joints with no pop rivets used. Duct sizes are calculated to accommodate permissible airflow speeds and required air volume relative to canopy area and cooking type. Fans are selected to overcome static pressure of the ducting system while still providing the required air volume.

CERTIFICATES OF COMPLIANCE

Certificates of compliance to SANS 1850 regulations can be issued subject to installation being carried out in full accordance with the specified design submitted.